Case IH 2000 Upgrade

Kit Explained

Follow along with Marion as he explains the Full Calmer BT Chopper® Upgrade Kit offered for the CASE IH 2200 & 2400 series corn heads. He describes in detail how the Calmer Upgrade Kit is one of the most advanced corn head systems in the world. With Calmer parts, not only will your older CASE IH corn head to perform better than a new head, but you’ll also make you more money in the process by reducing a pass across the field, eliminating the chopping of stalks, improving planting operations, and increasing yields. We guarantee your satisfaction or your money back!

Satisfaction Guaranteed or your money back!

Compatible with Case IH Models:

2206 – 2208 – 2212 – 2406 – 2408 – 2412 – 2416

3 STEPS

follow our recommended steps for maximum performance

Step 1

BT CHOPPER®

STALK ROLLS

Reliable stalk rolls are critical to a top-performing corn head. That’s why Calmer invented the World’s Only All-Weather Stalk Roll™ known as the BT Chopper®, which is the only roll in the industry with a patented “open window” feeding chamber for the superior feeding and processing of stalks in all crop conditions.

The 10 razor-sharp knives on each stalk roll cut, chop and shear cornstalks into confetti-like pieces for accelerated decomposition. As a result, you’ll be able to reduce a management pass across the field, improve your planting experience and increase yields.

STEP 2

MULTI-ZONE BEVELED STRIPPER PLATES

“We put the Calmer BT Chopper on our 2208. Halfway through Harvest, we purchased a 2212. We were so pleased with the performance of the Choppers that we put the ones off the 2208 onto the 2212, and hurried to pick up the extra 4 rows needed from Calmer. These work extremely well!”

Reduce Butt Shelling and

Decrease “Trash” Into Combine

Calmer’s Patented Multi-Zone Beveled Stripper Plates have a wider front opening that helps minimize the bulldozing of cornstalks when not fully aligned with the row. This wider retrieving area is manufactured flat in front to reduce ear wedging problems and beveled in the back stripping area to allow the stalk rolls to engage the ear shanks, leaves and husks. This significantly reduces trash intake into the combine. The patented beveled edge mimics the rounded bottom of the corn ear to help reduce butt shelling problems by displacing the energy around the base of the corn ear.

STEP 3

Slow Down Kit Chains and Sprockets

“We are really pleased with Calmer’s Trash Reduction Row-Unit Upgrade Kit. The kit took care of every problem we had. We installed it last season and it was the first season we had without stopping once to remove trash from the corn head. We wish we had installed it years ago.”

– Roger

Groton, South Dakota

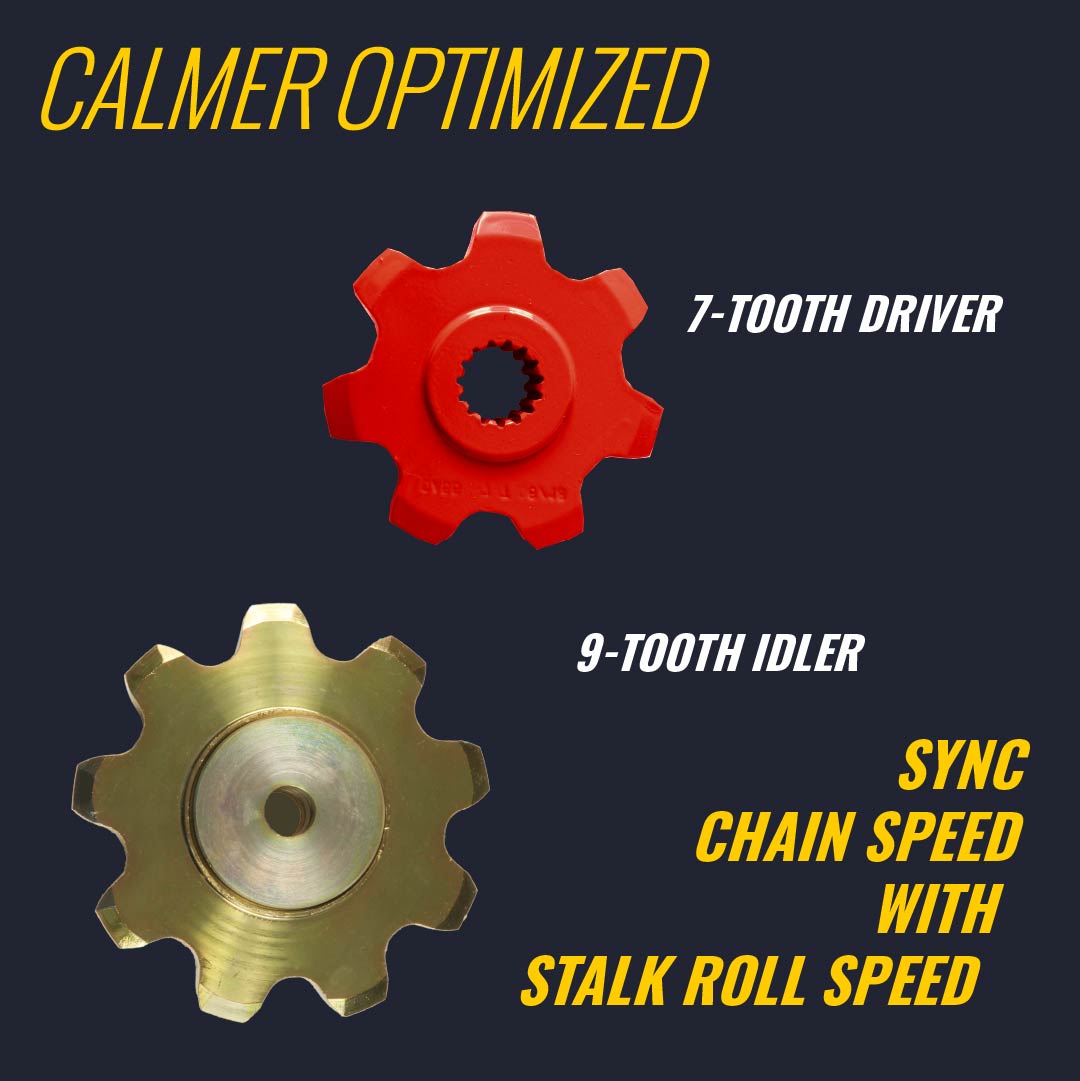

Calmer’s smaller 7-Tooth Drive Sprockets slow down gathering chains by 12.5% to reduce trash intake and kernel loss caused by excessive chain speed. Calmer’s larger 9-Tooth Idler Sprockets improve the chains’ grabbing and conveying ability and allow for a standard-size gathering chain to be used. This new-and-improved non-greaseable idler sprocket is solid-steel and has a replaceable bearing for increased life and lower maintenance. Longer-lasting Chrome-Pin Gathering Chains are sent with all Slow Down Kits.

Big picture Economics

Listen to George as he explains his thought process behind the economics of updating an older corn head with Calmer parts. According to him, his cost of ownership for rebuilding his corn head with Calmer Stalk Rolls and Residue Management Parts at only a $1 per acre!

Complete the ROI plan to see how

IT PAYS TO RUN CALMER PRODUCTS!

OEM PROBLEM

No Feeding Chamber

No stalk roll will perform properly without a feeding chamber in the entry area. All factory Case IH rolls have the same length flutes and therefore a continuous overlap in the entry area, which creates a wall of rotating steel and prevents the the entry and adequate processing of cornstalks.

Mechanically, this flawed design results in the premature wear in the first few inches of the stalk roll since stalks cannot travel further up the row unit.

Cornstalks CANNOT engage with factory rolls or become processed due to the continuous overlap in entry area.

CALMER SOLUTION

Patented “Open window” Feeding Chamber

Through in integration of multi-length blades, the Calmer BT Chopper® Stalk Roll is the only stalk roll on the market with a patented “open window” feeding chamber, which enables cornstalks to travel efficiently into the row unit to become processed.

This design performs in all crop conditions, guarantees the traction of stalks for processing, results in longer stalk roll life, reduces low ear snap, and prevents the bulldozing of stalks at the end rows.

Cornstalks EASILY engage with Calmer’s patented “open window” feeding chamber to become processed.

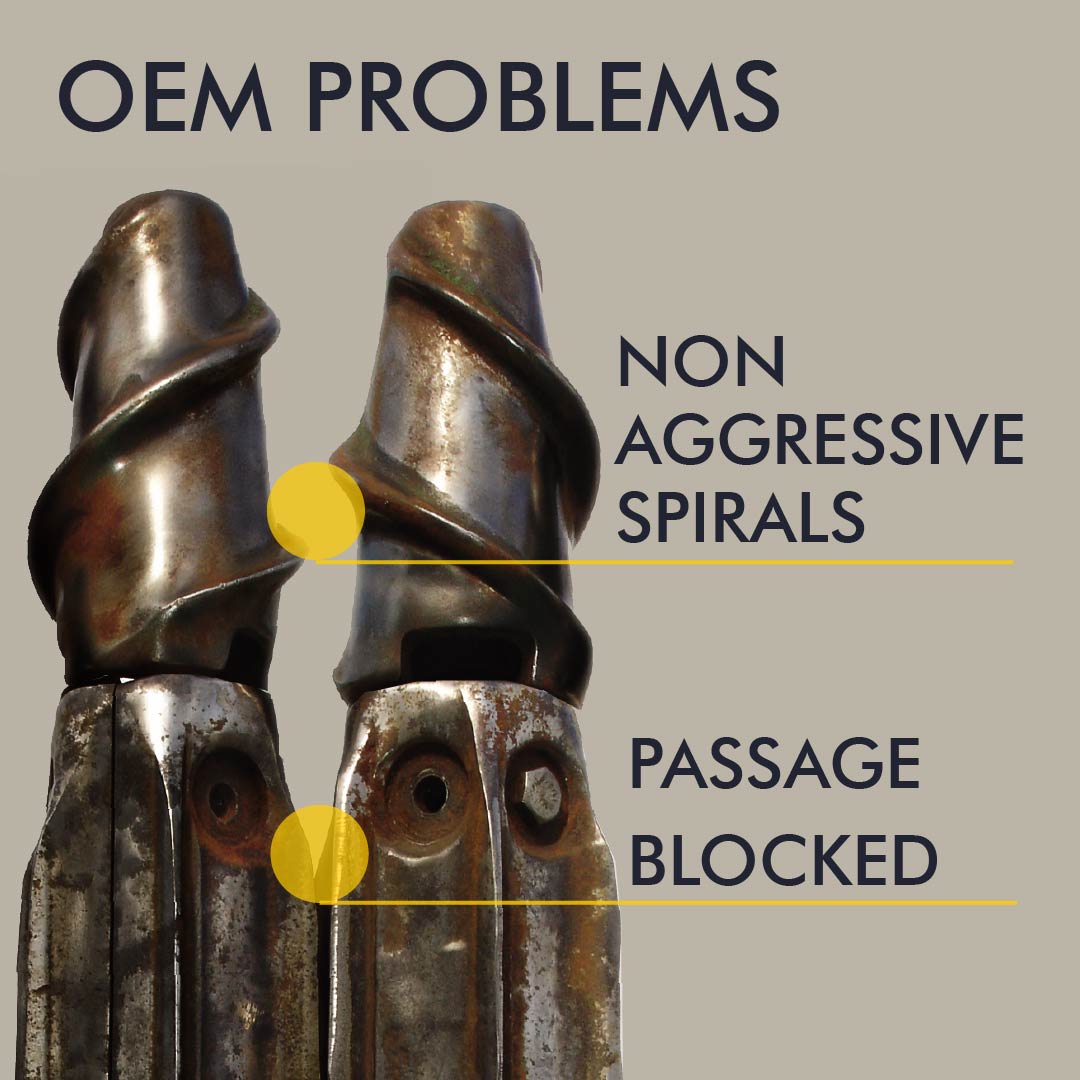

OEM PROBLEM

NON-AGGRESSIVE FLUTES

Limited Residue-to-Soil Contact

The stalk rolls on factory Case IH 2000 series corn heads have too much overlap in the entry area, which prevents cornstalks from engaging properly to become processed.

Failing to properly process cornstalks prevents residue-to-soil contact, leading to the immobilization of important nutrients on the soil surface, slower degradation rates and leaves a wet mattress of residue in the spring.

Cornstalks failed to enter the knife chamber, resulting in little residue-to-soil contact and slow decomposition rates.

CALMER SOLUTION

10 intermeshing Razor-sharp blades

Superior Residue to Soil Contact

During rotation, the shortened flutes on the Calmer BT Chopper are timed to create 2, 4-inch feeding chambers for an efficient handoff of the stalk into the 17 1/2-inch knife chamber to be processed.

In the knife chamber, 20 intermeshing, razor-sharp blades cut, chop, and shear cornstalks into confetti-like pieces. This process exposes the pith of the stalk and places the residue strategically over the row for superior residue-to-soil contact, accelerated decomposition, easier planting and higher yields!

Cornstalks are easily engaged and processed for superior residue-to-soil contact and rapid decomposition..

OEM PROBLEM

Fully-beveled STRIPPER PLATES

Factory Case IH 2000 series stripper plates have a full bevel from the front retrieving area to the back of the stripper plate.

This design is problematic as the full bevel can result in the lodging of ears in the front, which can occur frequently in down-corn and adverse crop conditions.

Factory Case IH 2000 plates have a full bevel from front to back that leads to increased ear lodging.

CALMER SOLUTION

Patented Multi-Zone Beveled Stripper Plates

Calmer’s Patented Multi-Zone Beveled Stripper Plates are flat in the front retrieving area to reduce ear wedging and beveled in the stripping area to allow the stalk rolls to engage more ear shanks, husks, and leaves. This helps significantly reduce trash intake into the combine.

Calmer’s patented beveled portion of the plate better mimics the rounded butt of the corn ear. This does a better job at displacing energy, which reduces kernel loss.

These beveled stripper plates are hardened for extended life.

Calmer Beveled Stripper Plates push more kernels toward the cob, reducing butt shelling and trash intake.

OEM PROBLEM

Excessive Gathering Chain Speed

With genetic enhancements, today’s corn hybrids are taller and drier and therefore more brittle during harvest time. Prior to 2008, corn heads utilized row units with speed ratios from the 1960s that used fast gathering chain speeds.

These fast gathering chain speeds often cause the gathering chain lug to make contact with the top of the plant before the stalk rolls have a chance to pull it below the stripper plates. This often results in increased trash intake or the breaking of stalks in certain crop conditions.

CALMER SOLUTION

patented slow down kit

Calmer sends a 7-Tooth Gathering Chain Drive Sprocket to slow down the gathering chains by 12.5%. This allows the stalk rolls to make additional revolutions to make more of the plant disappear below the stripper plates before the gathering chain lug can break it off and send additional trash into the combine.

We also recommend replacing the factory 8-tooth idler sprocket with Calmer’s Larger 9-Tooth Idler Sprocket which has a solid-steel design with a replaceable bearing to reduce wear on the idler block and increase the gathering chain lug’s grabbing ability in down corn.

Get MORE than you bargained for this fall with Calmer's BT Choppers® and Residue Management Upgrade Kits

With Calmer Upgrade Kits, you're getting more than just corn head parts, you're getting peace of mind that your residue management and corn head problems are solved for good during harvest.

Agronomic and Mechanical Advantages

Mechanical Advantages

- Compatible with all Tillage Systems

- 25% Less Hp Needed than with Chopping Heads

- Superior Cornstalk Flow to Engagement

- Better Ear Separation

- Less Tire Wear

- Less Butt Shelling

- Increased Harvesting Speeds (Achieved through a combination of installing Calmer® products and proper combine settings)

- Lower Spread Load

Agronomic Advantages

- Unmatched Residue Decomposition

- Warmer Soils

- Drier Soils

- Increased Earthworm Populations

- Reduced Nitrogen Penalty

- Easier Planting

- Higher Yields